Options and extended possibilities

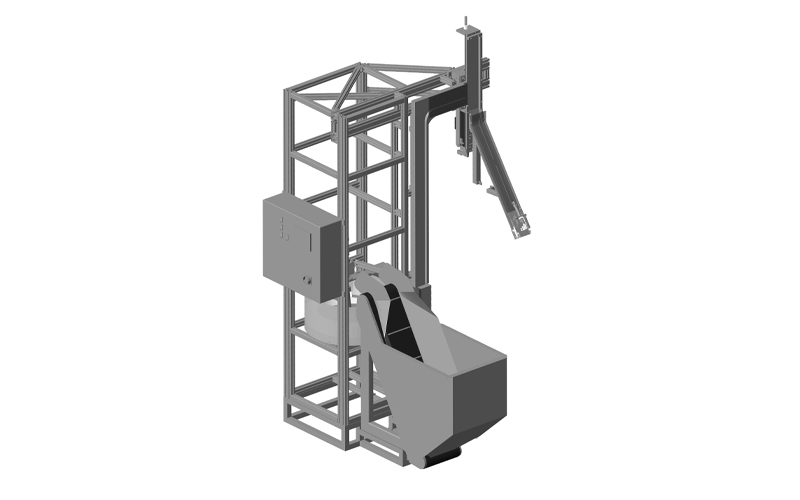

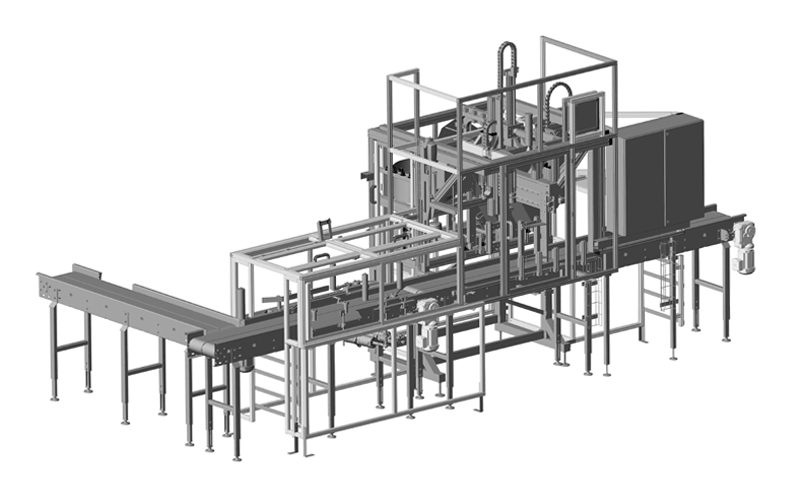

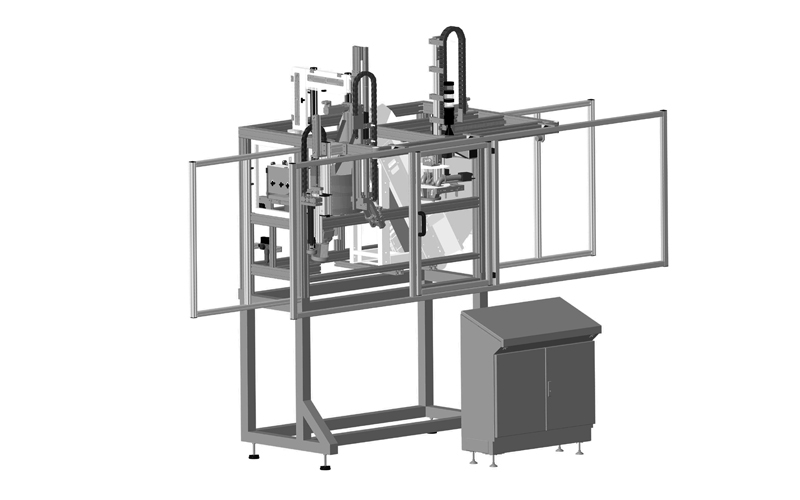

Individual special machinery for closing e.g. beer barrels, entirely according to your wishes

We will provide you with customised, customer-focussed solutions and an efficient, secure and durable closure system for your products. We can offer you options and extended solutions for your production, tailored precisely to fit your needs. Whether it is a matter of additional labelling for caps by means of an inkjet process, integrating a fully automatic height detection system or considering downstream cap inspection: Our team is always at your disposal and will implement your wishes and requirements to select the best SIGL machine for your needs.

You will find a brief overview of possible options and extended possibilities for SIGL special machinery here:

Cap monitoring

Tamper-proof closure is essential for your barrels, kegs and drums. Downstream cap inspection uses an electrical contact to check whether the cap encloses the fitting correctly.

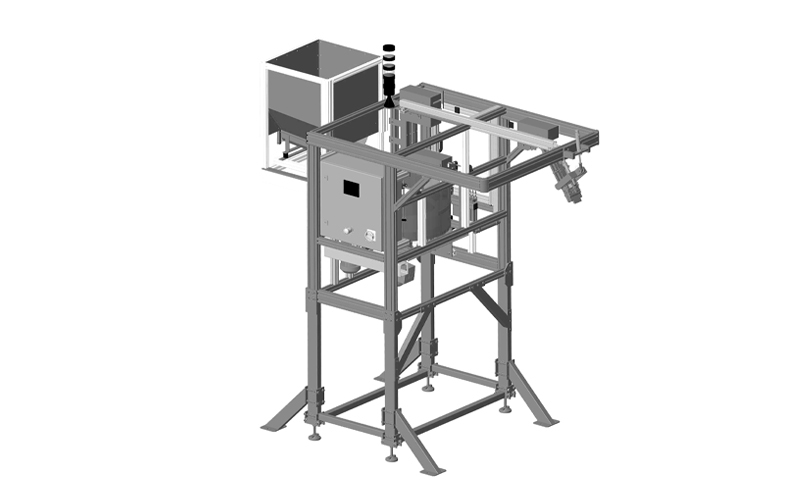

Height measurement

Even for one barrel size, there may be minor differences in height between barrels. Automatic height measurement compensates for these differences in an optimum manner.

Inkjet

Print the BBD, the date filled or even entire logos on your caps in a fully automated process, and on site. Thanks to our efficient partners, you will receive the ideal printer for your needs.

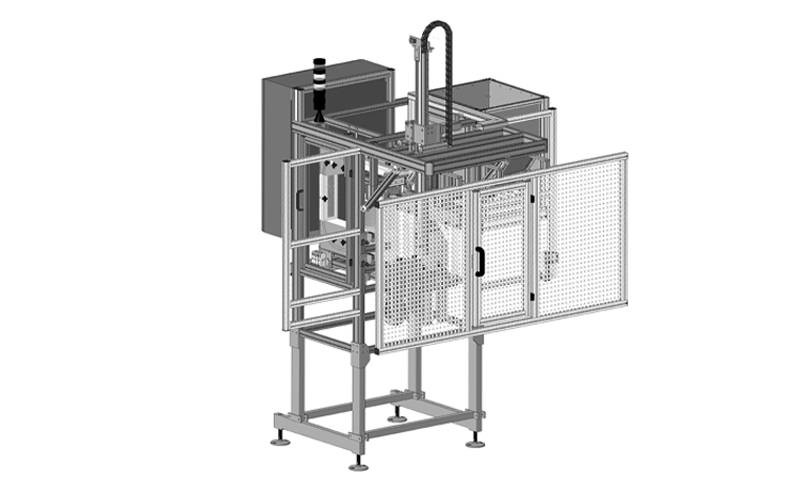

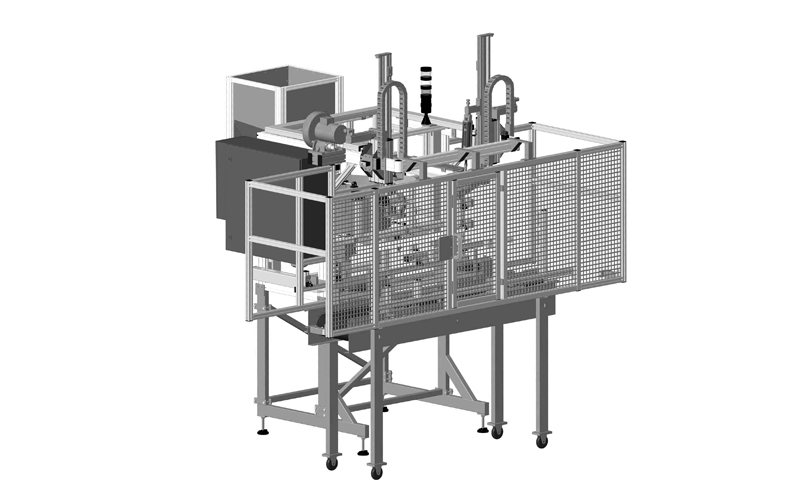

ENLARGING THE SUPPLY BUNKER

By using our optional supply bunker enlargement, you can easily optimise your picking and placement rhythm. Depending on the type of machinery, you can load up to 25% more caps/pass.

Laser marking

In cooperation with our partner DOMINOS, you will receive a modern laser system. This allows you to complete the full inscription process required for your caps on site. You can find out more about this here.

Remote maintenance

As an option, we can offer you secure remote maintenance via a VPN router. You activate remote maintenance by means of a key switch, so that there is no permanent connection to your company network and access can only be released by you when this is required.

WS interface

Weihenstephaner Standards (WS) provide a uniform communication interface that can be used by everyone. On request, we will implement WS in our machines.

Individual solutions

Do you still have a wish that you cannot find among these options? Do not hesitate to contact us. Our experienced team is always at your disposal.